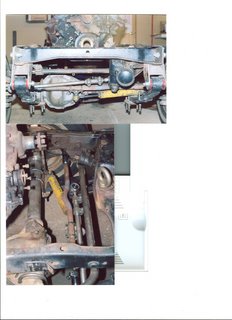

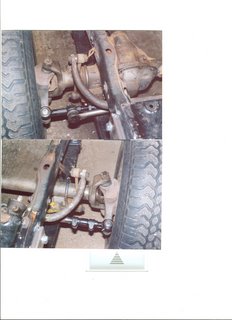

We picked up this 20 gal. poly. gas tank at the Blue Mountain Jeep Alliance  http://www.bmja.org/ yearly flea market in Orwigsburg for $20.00 and a skid plate from I guess a Wrangler at EZ Pull & Save in New Ringgold. (Phone 570-386-2171). All we had to do was lower the skid plate and change it from two hold down straps to one. A length of steel was added to the second crossmember to achieve this. Also sliced a little off the right side to clear the leaf springs. A new rear crossmember was fabricated from 2 x 4 box tubing. Just cut holes in for the frame rails and slid it on. Take notice we had to reverse the shackle mounts to clear the new crossmember because it is bigger than the frame. The centerline of the shackle pivot point was kept the same so as not to disturb the geometry. The old tub was set on to scribe a radius on the ends of the crossmember to match the body. This will give a bit more protection for the corner of the body and I never liked how the factory crossmember looked anyhow. We are also thinking about notching out the crossmember for the exhaust, this should look pretty trick. We'll just take a piece of pipe and slice it in half and notch out the crossmember and weld it in place, sort of muscle car era look.

http://www.bmja.org/ yearly flea market in Orwigsburg for $20.00 and a skid plate from I guess a Wrangler at EZ Pull & Save in New Ringgold. (Phone 570-386-2171). All we had to do was lower the skid plate and change it from two hold down straps to one. A length of steel was added to the second crossmember to achieve this. Also sliced a little off the right side to clear the leaf springs. A new rear crossmember was fabricated from 2 x 4 box tubing. Just cut holes in for the frame rails and slid it on. Take notice we had to reverse the shackle mounts to clear the new crossmember because it is bigger than the frame. The centerline of the shackle pivot point was kept the same so as not to disturb the geometry. The old tub was set on to scribe a radius on the ends of the crossmember to match the body. This will give a bit more protection for the corner of the body and I never liked how the factory crossmember looked anyhow. We are also thinking about notching out the crossmember for the exhaust, this should look pretty trick. We'll just take a piece of pipe and slice it in half and notch out the crossmember and weld it in place, sort of muscle car era look.

http://www.bmja.org/ yearly flea market in Orwigsburg for $20.00 and a skid plate from I guess a Wrangler at EZ Pull & Save in New Ringgold. (Phone 570-386-2171). All we had to do was lower the skid plate and change it from two hold down straps to one. A length of steel was added to the second crossmember to achieve this. Also sliced a little off the right side to clear the leaf springs. A new rear crossmember was fabricated from 2 x 4 box tubing. Just cut holes in for the frame rails and slid it on. Take notice we had to reverse the shackle mounts to clear the new crossmember because it is bigger than the frame. The centerline of the shackle pivot point was kept the same so as not to disturb the geometry. The old tub was set on to scribe a radius on the ends of the crossmember to match the body. This will give a bit more protection for the corner of the body and I never liked how the factory crossmember looked anyhow. We are also thinking about notching out the crossmember for the exhaust, this should look pretty trick. We'll just take a piece of pipe and slice it in half and notch out the crossmember and weld it in place, sort of muscle car era look.

http://www.bmja.org/ yearly flea market in Orwigsburg for $20.00 and a skid plate from I guess a Wrangler at EZ Pull & Save in New Ringgold. (Phone 570-386-2171). All we had to do was lower the skid plate and change it from two hold down straps to one. A length of steel was added to the second crossmember to achieve this. Also sliced a little off the right side to clear the leaf springs. A new rear crossmember was fabricated from 2 x 4 box tubing. Just cut holes in for the frame rails and slid it on. Take notice we had to reverse the shackle mounts to clear the new crossmember because it is bigger than the frame. The centerline of the shackle pivot point was kept the same so as not to disturb the geometry. The old tub was set on to scribe a radius on the ends of the crossmember to match the body. This will give a bit more protection for the corner of the body and I never liked how the factory crossmember looked anyhow. We are also thinking about notching out the crossmember for the exhaust, this should look pretty trick. We'll just take a piece of pipe and slice it in half and notch out the crossmember and weld it in place, sort of muscle car era look.