This post will get a bit technical so if part numbers and details bore you, you might want to move on. If you think you might like to duplicate a steering set-up like this then I can save you a lot of aggravation and money on Advil, read on because this turned out pretty sweet.

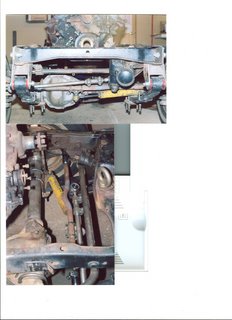

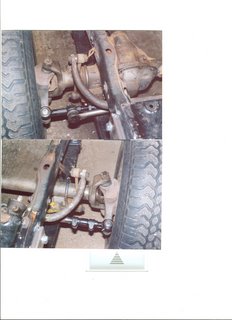

Do in part to switching to Dana 44's and keeping the Wagoneer spindles we ended up with only one tie rod end hole on the passenger side instead of two like the CJ. This proved to be troublesome in figuring out a tie rod set up. The Wagoneer tie rod has an intregrated tie rod end and would have to be shortened. We wanted to eliminate problems in the future when a tie rod end goes bad that another custom tie rod wouldn't have to be made plus the down time. Also with the shackle reversal moving the axle forward 1 1/2" brought the tie rod that much closer to the pitman arm. I see now why M.O.R.E.

http://www.mountainoffroad.com/ doesn't recommend a dropped pitman arm, it would obviously hit the tie rod. But we wanted to keep everything as parallel as possible to eliminate bump steer with the 2" lift and that meant a dropped arm. The dropped arm came from a 1987 Wrangler (square headlight) as did the beefier sway bar. The good old boys at B & S Auto Parts in Pine Grove loaned me an extra spicer parts book and after a few nights of reading and measuring I decided on a tie rod end incorporating a tapered hole for a drag link for a 1/2 ton Chevy. This gave me the same size ball end as a Wagoneer (bigger than a CJ) and the extra hole that was needed for the drag link that was eliminated off the spindle. (Spicer part number 401-1275. cost $18.29) The only problem is that this end is designed for the driver side of the Chevy thus the tapered hole, which was designed for a steering dampener was facing the wrong way, but happened to be smaller than the draglink tapered end. The hole had to be enlarged from the other end. So I did some searching for tapered reamers and found what I needed on Ebay. Damn isn't technology great? The reamer is an Xcut brand #5952, 1 1/2" taper per foot, bought from Ebay seller tltrades at his Ebay store XKUT for $47.99. I measured with a dial calipers what the large diameter of the hole should be and put a piece of tape on the reamer to get the depth, then mounted the tie rod end on a drill press and slowly reamed it out. The driverside tie rod end is a Spicer part number 401-1134, cost $34.89. The main tie rod is the only mildly custom part, but if you never damage it, will never need to be replaced. It is made from a 1979 Jeep J10. I have seen these in 2 versions totally straight or a bend to give extra clearance for the pitman arm, get the straight one. Cut off the end with the lefthand thread to a length of 32" and have the end rethreaded 7/8 - 18 left hand, this will be the only machine shop work performed, unless you have access to one. I am a machinist by trade so I was able to take it to work and wrote a program for a cnc lathe and thread it there. You will also have to put a bend in it, at a 13" centerline from the lefthand threaded end to clear the pitman arm. ( Of course do this after it's rethreaded or you wont be able to chuck it in a lathe.) The bend was perfomed with a hydraulic pipe bender from Harbor Freight http://harborfreight.com/ item number 32888-svga cost $74.99 and a little bit of heat. The tie rod end and tie rod are connected with Spicer adjuster sleeves part number 425-1002 cost $7.33 each. The drag link is a Spicer part number 405-1009 cost $46.00. The threaded end was shortened by 1" and rethreaded with a 7/8 - 18 righthand die purchased from MSC http://www1.mscdirect.com/cgi/nnsrhm part number 03938180 cost $32.62. A Spicer tie rod end, part number 401-1224 cost $49.88 and another adjuster sleeve rounds out the drag link. Connect this end to the Wrangler pitman arm. As you can see everything is pretty well parallel and as the suspension travels the pitman arm now clears the bend in the main tie rod. You can also install a shock dampener and brackets from a J10 with no clearance issues. The sway bar from the Wrangler can be mounted in the stock location on the frame, but the legs are straight unlike the curved down ones on a CJ requiring longer connecting links and is also wider. Well it just happens that unmodified links from a J10 are the correct length, but will have to be mounted on the inside of the swaybar instead of the outside. The tapered holes in the sway bar are facing the wrong way for this. You know that reamer that was purchased for the tie rod end? Yep, same size, just mount on a drill press and ream half way thru and the tapered bolt can then be used from the J10. This makes for one beefy set up with full adjustability, and readily available replacement parts that can be easily modified at home.

2 Comments:

Really amazing! Useful information. All the best.

»

Hey what a great site keep up the work its excellent.

»

Post a Comment

<< Home